top of page

Latest From Us.

Custom-fit carbon fibre face masks made with PolyMorphic moulding

The problem Custom-fit protective face masks for sports are costly and uncommon outside professional levels due to several factors, primarily involving the manufacturing process, technological requirements, and the intricacies of 3D printing and scanning. The manufacturing of these masks begins with a detailed 3D scan of the athlete's face. This process captures precise facial dimensions to ensure a perfect fit, essential for both comfort and safety. High-resolution 3D scanne

Tom Bunting

Jun 8, 20242 min read

Comparing PolyMorphic moulding to conventional manufacturing methods

The Problem Low volume production is expensive if not uneconomical in some cases. Fyous ran a case study comparing 3D printing and traditional mould making of an RC (Remote control) car body to PolyMorphic moulding. The part was printed in both MJF and FDM, and then a PolyMorphic mould was made for vacuum forming out of recycled plastic. FDM Machine: Bambu labs X1 Carbon Time: 7 hours Cooling & Post processing: 10 minutes Wastage: 50% Cost: £7 per part MJF Machine: HP5210 T

Tom Bunting

Jun 5, 20241 min read

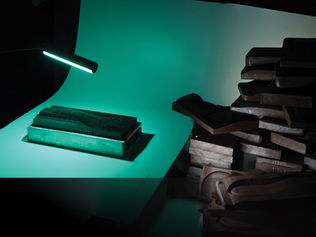

Reducing waste and time for product development with PolyMorphic Moulding

The problem Moulds are expensive and 100% waste once they are no longer useful. To prototype foam products you need to make a mould (or mold if you are from the USA!). Moulds can be made from a variety of materials but typically for prototyping you would use silicone in combination with a 3D printed master part. As you're prototyping, you will iterate the design and have to 3D print a new master and remake the moulds which is time consuming. It is also very wasteful due to t

Tom Bunting

Jun 3, 20242 min read

bottom of page