PolyMorphic Moulding.

One Tool, Infinite Possibilities.

Form any shape in minutes.

replaces fixed tooling with shapeshifting moulds

made from thousands of pins. With digital control over every pin,

you can form and reconfigure tools in minutes to produce custom

parts more efficiently than ever.

replaces fixed tooling with shapeshifting moulds made from thousands of pins. With digital control over every pin, you can form and reconfigure tools in minutes to produce custom parts more efficiently than ever.

[01]

Proprietary technology with multiple patents pending.

[02]

Scalable solutions that can be configured to your requirements.

[03]

Micron accuracy with pins as small as 0.3mm in diameter.

[04]

Force resistant moulds that withstand 6+ tonnes of distributed pressure.

[05]

Achieve undercuts with multi-sided tool configurations.

[06]

Faster production that delivers parts up to 24× quicker than 3D printing.

[01]

Proprietary technology with multiple patents pending.

[02]

Scalable solutions that can be configured to your requirements.

[03]

Micron accuracy with pins as small as 0.3mm in diameter.

[04]

Force resistant moulds that withstand 6+ tonnes of distributed pressure.

[05]

Achieve undercuts with multi-sided tool configurations.

[06]

Faster production that delivers parts up to 24× quicker than 3D printing.

01

Produce custom tooling in minutes, not weeks.

02

Store your mould inventory on your desktop.

03

Achieve cost-effective mass customisation.

04

Iterate freely without the limits of traditional tooling.

Key Benefits

Produce bespoke tooling in minutes, not weeks.

Store your mould inventory on your desktop.

Achieve cost-effective mass customisation.

Iterate freely without the limits of traditional tooling.

Applications

HOLD ANY SHAPE

Workholding

PolyMorphic Tooling adapts instantly to complex geometries - ideal for work holding in machining, metrology, inspection, and assembly. No clamps. No custom jigs. Just precision and repeatability.

MOULDS IN MINUTES

Vacuum Forming

Create fully reconfigurable forming beds in minutes. Fyous tooling replaces traditional moulds with an infinitely reusable, pin-based surface - perfect for prototyping and low-volume runs.

SHAPE HIGH-PERFORMANCE MATERIALS

Composite Forming

Support carbon fibre layups and reinforced materials with tooling that conforms to your part. Fyous enables rapid iteration, custom curvature, and accurate cures - with zero waste.

HOLD ANY SHAPE

Workholding

PolyMorphic Tooling adapts instantly to complex geometries - ideal for work holding in machining, metrology, inspection, and assembly. No clamps. No custom jigs. Just precision and repeatability.

MOULDS IN MINUTES

Vacuum Forming

Create fully reconfigurable forming beds in minutes. Fyous tooling replaces traditional moulds with an infinitely reusable, pin-based surface - perfect for prototyping and low-volume runs.

SHAPE HIGH-PERFORMANCE MATERIALS

Composite Forming

Support carbon fibre layups and reinforced materials with tooling that conforms to your part. Fyous enables rapid iteration, custom curvature, and accurate cures - with zero waste.

Applications

Learn more about Polymorphic Manufacturing and what this means for the future of production.

Download Whitepaper

Infinitely Reconfigurable

Manufacturing.

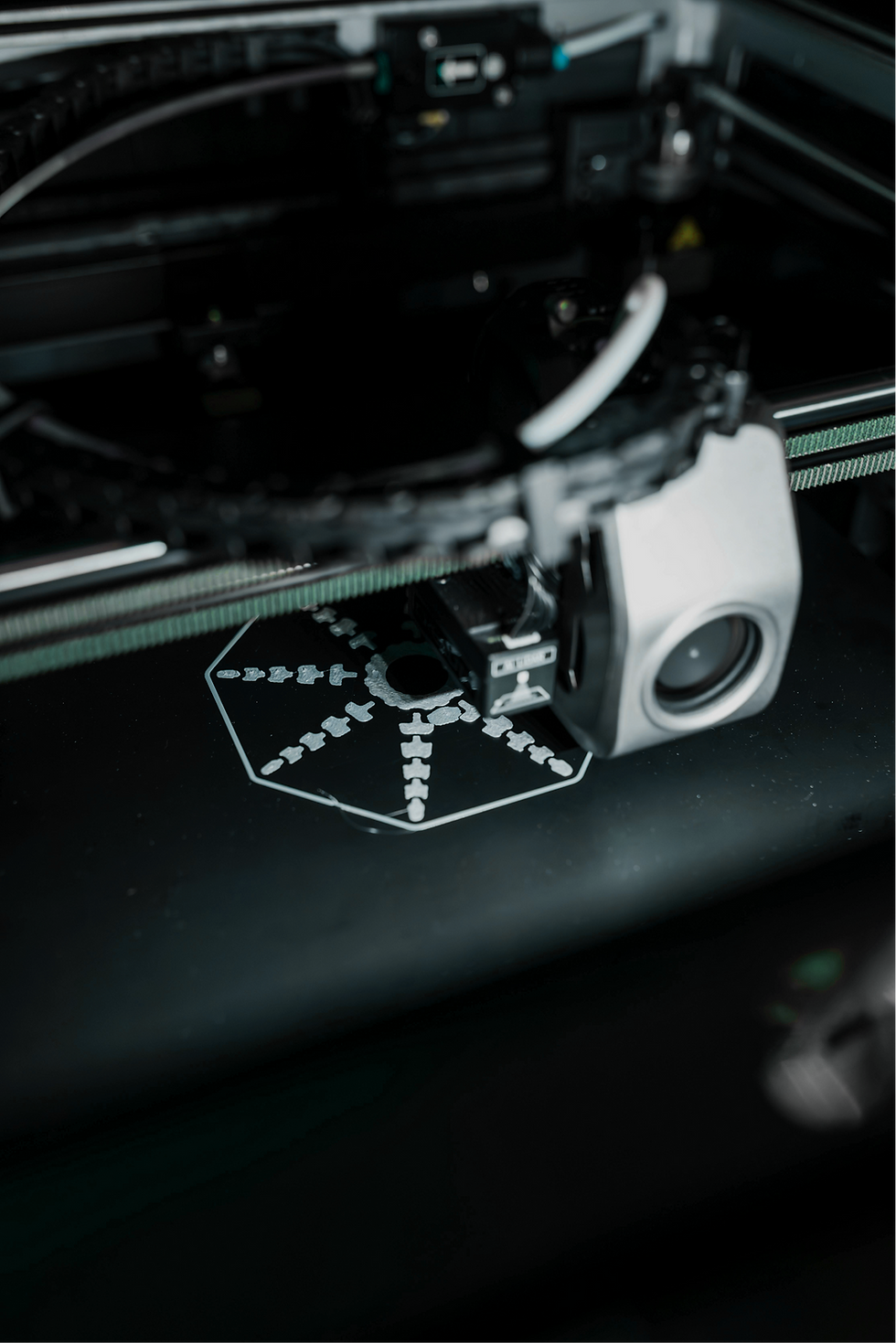

Polymorphic Technology substitutes traditional tooling with a digitally-controlled pin array, enabling engineers to go from design to part in minutes, not months. Thousands of digitally controlled pins morph into unique shapes.

01

02

03

04

SOFTWARE

Pin Point

Polymorphic Technology substitutes traditional tooling with a digitally-controlled pin array, enabling engineers to go from design to part in minutes, not months. Thousands of digitally controlled pins morph into unique shapes.

POLYMORPHIC

Forming Machine

Polymorphic Technology substitutes traditional tooling with a digitally-controlled pin array, enabling engineers to go from design to part in minutes, not months. Thousands of digitally controlled pins morph into unique shapes.

APPLICATIONS

Use the Mould

Polymorphic Technology substitutes traditional tooling with a digitally-controlled pin array, enabling engineers to go from design to part in minutes, not months. Thousands of digitally controlled pins morph into unique shapes.

RECONFIGURE

Reset & Re-use

Polymorphic Technology substitutes traditional tooling with a digitally-controlled pin array, enabling engineers to go from design to part in minutes, not months. Thousands of digitally controlled pins morph into unique shapes.

How It Works

PinPoint™

Our proprietary software enables you to seamlessly introduce PolyMorphic Technology into your production process.

STEP 1

Upload .STL

Start by uploading an STL file of the forms you require. This can be done one by one or in batches dependent on your desired workflow.

STEP 2

Input .FCode

PinPoint then converts your files into FCode. This sets the precise height of each pin individually, configuring the PolyMorphic tools according to your STL file.

Produce bespoke tooling in minutes, not weeks.

Store your mould inventory on your desktop.

Achieve cost-effective mass customisation.

Iterate freely without the limits of traditional tooling.

STEP 1

Upload .STL

Start by uploading an STL file of the forms you require. This can be done one by one or in batches dependent on your desired workflow.

STEP 2

Input .FCode

PinPoint then converts your files into FCode. This sets the precise height of each pin individually, configuring the PolyMorphic tools according to your STL file.

Where Else Is This Possible?

HOLD ANY SHAPE

Workholding

PolyMorphic Tooling adapts instantly to complex geometries - ideal for work holding in machining, metrology, inspection, and assembly. No clamps. No custom jigs. Just precision and repeatability.

Watch Video

MOULDS IN MINUTES

Vacuum Forming

Create fully reconfigurable forming beds in minutes. Fyous tooling replaces traditional moulds with an infinitely reusable, pin-based surface - perfect for prototyping and low-volume runs.

Watch Video

SHAPE HIGH-PERFORMING MATERIALS

Composites

Support carbon fibre layups and reinforced materials with tooling that conforms to your part. Fyous enables rapid iteration, custom curvature, and accurate cures - with zero waste.

Watch Video

Let's Explore the

Possibilites Together.

Let's Explore the

Possibilites Together.

Shaping the Answers.

If your question hasn’t been answered, feel free to message us directly at support@fyous.com.

Yes. The pins are made from an alloy which is resistant to liquid damage and rust.

This is achieved with a flexible membrane sitting either directly on top of the pins or around the material injection nozzle, ensuring the material adopts the shape of the mould.

This is one of the questions we get most often. It is explained best here.

This varies depending on several things including pin diameter, pin density and membrane thickness (if used). You can achieve a virtually imperceivable pin imprint from your mould with the right machine configuration, which we’d be happy to help with: Bespoke Solutions

Yes, our proprietary PinPoint software is included with all machine purchases. The easy-to-use software enables you to quickly load your STIL files to your Fyous machine.

This is technically unlimited depending on machine configuration. Pin arrays can be built as small or large as required, depending on your application.

This is limited by the machines pin actuation mechanism, which can be configured to complete in as little as 5 minutes. The standard PF-01 takes ~20 minutes to configure 28,000 pins.

PolyMorphic tools require zero material consumable to form their required shape. They therefore achieve a major leap forward in sustainability and huge reduction in waste production.