Shaping Solutions

Across Every Industry.

Industries We Serve

01

Orthotics manufacturing is often slow, manual, and difficult to scale - especially when precision or patient customisation is required. Fyous changes that, enabling fully automated, reconfigurable production with no need for moulds or tooling.

Whether you're running a high-volume lab or creating bespoke insoles on demand, our technology flexes to fit - improving consistency, cutting waste, and accelerating delivery.

02

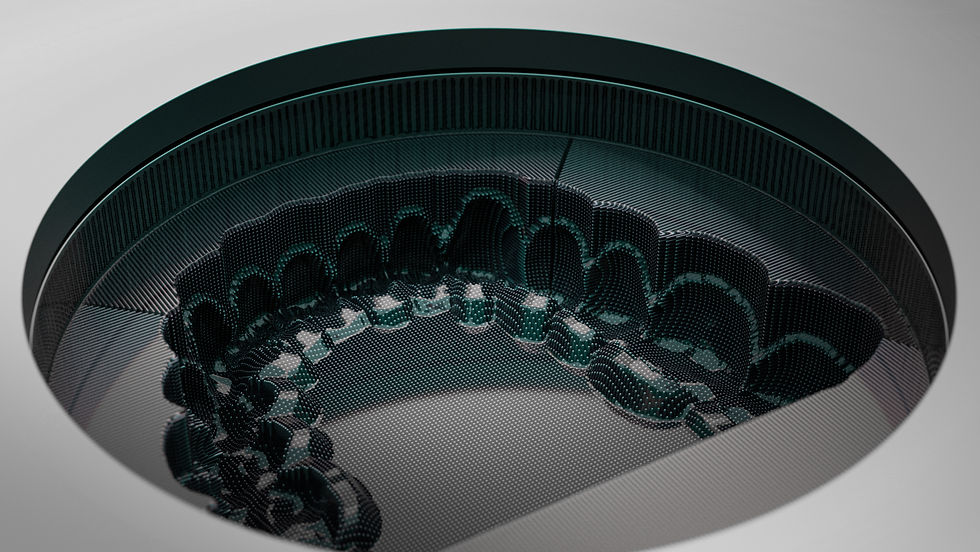

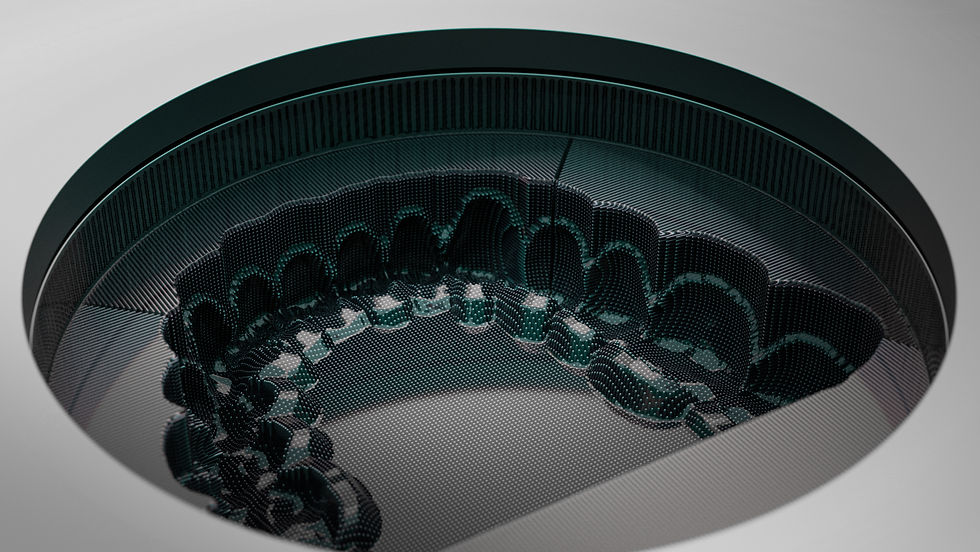

Dental appliances require high precision, individualisation, and rapid turnaround - but conventional manufacturing still relies heavily on fixed moulds, manual labour, and time-consuming workflows. Fyous enables a new kind of production: fully digital, infinitely reconfigurable, and built for scale.

Ideal for clear aligners, mouthguards, or night splints, our moulding platform adapts in minutes, reducing setup time and enabling true made-to-order efficiency.

03

Footwear manufacturing struggles with balancing mass production and individual fit - especially for orthopaedics, performance shoes, or custom lasts. Traditional methods are slow to adapt, tooling is expensive, and waste is high. Fyous changes the model entirely: with PolyMorphic Manufacturing, each sole or last is formed on demand using digitally controlled pins, no mould swap required.

Best for brands pushing customisation, orthotic labs, or performance manufacturers seeking lean, responsive production at scale.

04

Bringing medical devices to market often involves long lead times, costly tooling, and production methods that can’t flex with iterative design or patient-specific needs. Fyous enables fast, adaptive manufacturing of custom components without the need for new moulds - ideal for pilot runs, low-volume parts, or anatomically tailored devices.

Whether you're producing patient-specific grips, housings, or enclosures, our PolyMorphic systems offer a precise, clean, and scalable alternative. Best for MedTech startups, design engineers, and OEMs looking to innovate quickly and responsibly.

05

Traditional moulding techniques limit creative freedom and are often too slow or expensive for short runs or iterative work. Fyous gives artists, designers, and fabricators a new way to bring complex, customised forms to life - without waiting on tooling or compromising on shape.

Our PolyMorphic system forms intricate designs in minutes, enabling rapid exploration and efficient production of bespoke pieces. Best for studios, set designers, experimental fabricators, and anyone working at the intersection of creativity and manufacturing.

06

In aerospace, precision and adaptability are everything - but traditional tooling can be slow, rigid, and expensive to change. Fyous enables rapid, on-demand forming of complex components with no need for fixed moulds, making it easier to prototype, iterate, or produce low-volume parts without long lead times.

Our system is ideal for lightweight structural components, custom interiors, or testing parts where shape variation is key. Best for aerospace R&D teams, lightweight materials engineers, and contractors building for the edge of what's possible.

07

The automotive industry is shifting toward agility - but legacy tooling still locks manufacturers into high costs and inflexible setups. Fyous offers a faster, more adaptable way to produce custom or low-volume parts, enabling on-demand forming without the need for traditional moulds.

From concept vehicles to interior trims and ergonomic components, our technology supports leaner development cycles and broader customisation. Best for innovation teams, electric vehicle startups, and automotive suppliers seeking speed without sacrificing precision.

08

In research and development, speed and flexibility are everything - but conventional tooling slows down experimentation. Fyous enables rapid iteration with infinitely reconfigurable moulds that adapt in minutes, giving R&D teams the power to prototype and test custom geometries without committing to fixed tools.

Whether you're exploring new materials, testing biomechanics, or pushing the boundaries of what's possible in your field, our system reduces cost, increases throughput, and accelerates time to insight. Ideal for innovation labs, academic institutions, and advanced material or process development teams.

03

Footwear

04

Medical Services

05

Art & Design

06

Aerospace

07

Automotive

08

R&D

Hover

Industries We Serve

Orthotics manufacturing is often slow, manual, and difficult to scale - especially when precision or patient customisation is required. Fyous changes that, enabling fully automated, reconfigurable production with no need for moulds or tooling.

Whether you're running a high-volume lab or creating bespoke insoles on demand, our technology flexes to fit - improving consistency, cutting waste, and accelerating delivery.

01

Dental appliances require high precision, individualisation, and rapid turnaround - but conventional manufacturing still relies heavily on fixed moulds, manual labour, and time-consuming workflows. Fyous enables a new kind of production: fully digital, infinitely reconfigurable, and built for scale.

Ideal for clear aligners, mouthguards, or night splints, our moulding platform adapts in minutes, reducing setup time and enabling true made-to-order efficiency.

02

01

Orthodontics

02

Dental

03

Footwear

04

Medical Services

05

Art & Design

06

Aerospace

07

Automotive

08

Research & Development

Hover

Industries We Serve

Orthotics manufacturing is often slow, manual, and difficult to scale - especially when precision or patient customisation is required. Fyous changes that, enabling fully automated, reconfigurable production with no need for moulds or tooling.

Whether you're running a high-volume lab or creating bespoke insoles on demand, our technology flexes to fit - improving consistency, cutting waste, and accelerating delivery.

Dental appliances require high precision, individualisation, and rapid turnaround - but conventional manufacturing still relies heavily on fixed moulds, manual labour, and time-consuming workflows. Fyous enables a new kind of production: fully digital, infinitely reconfigurable, and built for scale.

Ideal for clear aligners, mouthguards, or night splints, our moulding platform adapts in minutes, reducing setup time and enabling true made-to-order efficiency.

Footwear manufacturing struggles with balancing mass production and individual fit - especially for orthopaedics, performance shoes, or custom lasts. Traditional methods are slow to adapt, tooling is expensive, and waste is high. Fyous changes the model entirely: with PolyMorphic Manufacturing, each sole or last is formed on demand using digitally controlled pins, no mould swap required.

Best for brands pushing customisation, orthotic labs, or performance manufacturers seeking lean, responsive production at scale.

Bringing medical devices to market often involves long lead times, costly tooling, and production methods that can’t flex with iterative design or patient-specific needs. Fyous enables fast, adaptive manufacturing of custom components without the need for new moulds - ideal for pilot runs, low-volume parts, or anatomically tailored devices.

Whether you're producing patient-specific grips, housings, or enclosures, our PolyMorphic systems offer a precise, clean, and scalable alternative. Best for MedTech startups, design engineers, and OEMs looking to innovate quickly and responsibly.

Traditional moulding techniques limit creative freedom and are often too slow or expensive for short runs or iterative work. Fyous gives artists, designers, and fabricators a new way to bring complex, customised forms to life - without waiting on tooling or compromising on shape.

Our PolyMorphic system forms intricate designs in minutes, enabling rapid exploration and efficient production of bespoke pieces. Best for studios, set designers, experimental fabricators, and anyone working at the intersection of creativity and manufacturing.

In aerospace, precision and adaptability are everything - but traditional tooling can be slow, rigid, and expensive to change. Fyous enables rapid, on-demand forming of complex components with no need for fixed moulds, making it easier to prototype, iterate, or produce low-volume parts without long lead times.

Our system is ideal for lightweight structural components, custom interiors, or testing parts where shape variation is key. Best for aerospace R&D teams, lightweight materials engineers, and contractors building for the edge of what's possible.

The automotive industry is shifting toward agility - but legacy tooling still locks manufacturers into high costs and inflexible setups. Fyous offers a faster, more adaptable way to produce custom or low-volume parts, enabling on-demand forming without the need for traditional moulds.

From concept vehicles to interior trims and ergonomic components, our technology supports leaner development cycles and broader customisation. Best for innovation teams, electric vehicle startups, and automotive suppliers seeking speed without sacrificing precision.

In research and development, speed and flexibility are everything - but conventional tooling slows down experimentation. Fyous enables rapid iteration with infinitely reconfigurable moulds that adapt in minutes, giving R&D teams the power to prototype and test custom geometries without committing to fixed tools.

Whether you're exploring new materials, testing biomechanics, or pushing the boundaries of what's possible in your field, our system reduces cost, increases throughput, and accelerates time to insight. Ideal for innovation labs, academic institutions, and advanced material or process development teams.

The Problem

Across every industry, traditional manufacturing locks you into fixed tooling, long lead times, and high upfront costs - limiting your ability to customise, iterate, or scale. When products demand precision and speed, outdated systems just can’t keep up.

The Solution

Fyous replaces rigid tools with intelligent, reconfigurable moulds - ready to form any shape, any time. Our technology brings speed, flexibility, and digital control to every production line, giving you a new standard of custom manufacturing without compromise.

Discover Our

Range of Machines.

PF-01

PM-01

Custom

Technical Partnerships

for Tailored Solutions:

Peacocks Case Study

The Challenge

Orthopaedic footwear manufacturers face a long-standing problem: producing custom shoe lasts is labour-intensive, wasteful, and difficult to scale. Traditional CNC milling processes are subtractive by nature, and each shoe last requires significant manual input. Labour costs often make up as much as 80% of the total cost of production. Peacocks Medical Group are a leader in orthopaedic footwear who are held back by the limitations of existing technology. They needed a new approach that would automate production, reduce material waste, and deliver consistent results.

The Partnership Approach

Recognising the potential of PolyMorphic Moulding as a solution, Fyous and Peacocks formed a technical partnership to solve this industry-wide problem. Peacocks agreed to act as the first industry adopter and together we entered a 12-week discovery process. We worked closely with Peacocks’ technical and operations teams to understand their production environment in detail.

The Solution

The machine we were to build had to be judged on measurable outcomes. We therefore agreed requirements including:

01

Throughput

02

Automation Level

03

Material Efficiency and Waste

04

Output Consistency and Quality

05

Material Traceability

The Impact

The benefits are clear for Peacocks. Rather than a labour-intensive and wasteful milling process, they will be able to run automated production runs, freeing up skilled technicians to focus on higher-value tasks. The move to PolyMorphic Moulding will cut waste dramatically, all whilst driving down unit costs and expanding production capacity. The partnership shows how Fyous works: immersing ourselves in an industry, understanding its challenges, and co-creating solutions that deliver serious impact.

The Solution

The machine we were to build had to be judged on measurable outcomes. We therefore agreed requirements including:

The Impact

The benefits are clear for Peacocks. Rather than a labour-intensive and wasteful milling process, they will be able to run automated production runs, freeing up skilled technicians to focus on higher-value tasks. The move to PolyMorphic Moulding will cut waste dramatically, all whilst driving down unit costs and expanding production capacity. The partnership shows how Fyous works: immersing ourselves in an industry, understanding its challenges, and co-creating solutions that deliver serious impact.

01

Throughput

01

Automation Level

01

Material Efficiency and Waste

01

Output Consistency and Quality

01

Material Traceability

Build It Custom

Have a production that needs particular requirements? We custom build machine equipt with Polymorphic technology for your factories every need.